AEROSPACE FINISHING SERVICES IN RANCHO CUCAMONGA, CA

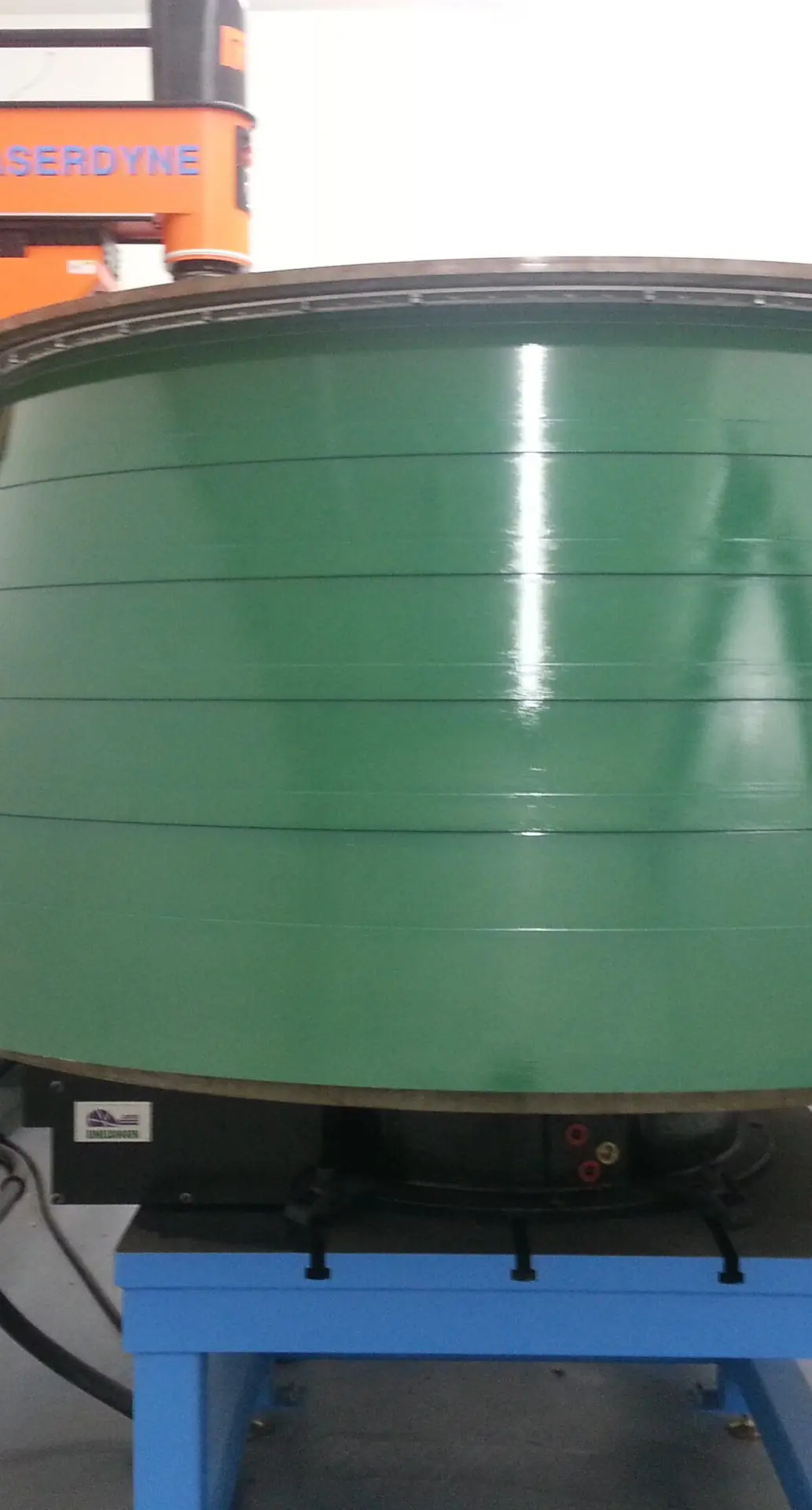

Precision Aerospace Corporation in Rancho Cucamonga, CA, provides state-of-the-art finishing services, including:

- Aerospace metal finishers

- Aerospace surface finish

AEROSPACE SURFACE FINISH

As a company that has provided metal finishing solutions to the aerospace industry for decades, we at Precision Aerospace Corporation in Rancho Cucamonga, CA, understand the need for superior quality and precision with defect-free surface finishing.

Surface finishing is a critical part of the aerospace industry regarding the safety and functionality of equipment and components used in aircraft and spacecraft.

Where are aerospace surface finishers and aerospace metal finishers used?

- Guidance and navigation systems

- Fuel nozzles

- Engine components

- Landing gear assemblies

- Rotor blades

- Communications controls and instruments

- Electrical hardware

Aerospace engineering requires precision. Every part used in the air or space needs protection against corrosion, wear resistance, uniform coverage, and friction reduction while moving.

CORROSION PROTECTION

Precision uses cadmium, zinc, or zinc-nickel coatings that withstand extreme exposure. These materials cause minimal corrosion on any surface they come into contact with. They also serve as a sacrificial coating that corrodes before the metal it covers begins to erode. An aluminum anodizing process makes them even more durable and less susceptible to corrosive elements.

RESIST WEAR

Precision Aerospace Corporation applies chrome, nickel, or electroless nickel coatings to increase surface hardness and protect components from surface damage. Silver plating threads on igniter parts prevent them from cold welding or seizing inside the engine, allowing removal after high-temperature exposure.

UNIFORM COVERAGE

PAC uses a special nickel plating to allow for even application to the surface without using an external electrical charge. This process ensures excellent resistance to corrosion or other damage.

FRICTION REDUCTION

When we reduce friction, the aircraft or spacecraft part also becomes more resistant to corrosion and wear.

Precision Aerospace Corporation applies dry film lubricants, PTFE-sealed hard coat anodize, or PTFE co-deposited electroless nickel to pieces to reduce friction. These parts include slide mechanisms on rotating machinery, fasteners, and cables.

PAC maintains NADCAP accreditation for chemical processes.

We use surface coatings on the following:

- Commercial aircraft

- Missiles

- Satellites

- Military aircraft

- Radar systems

- Spacecrafts

We specialize in the following:

- Anodizing

- Electroless Nickel

- Hard Chrome

- Cadmium

- Zinc/Nickel

- Electrolytic Nickel

- Dry Film Lubricants

LET US FINISH YOUR PROJECT

Select the right finish for your aerospace project. Contact Precision Aerospace Corporation in Rancho Cucamonga, CA, today to learn how our aerospace surface finishing can help you.

CALL NOW +1 909-980-8855